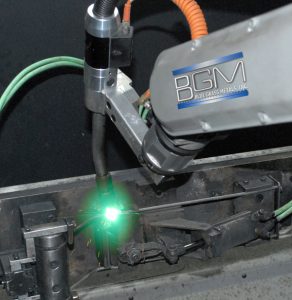

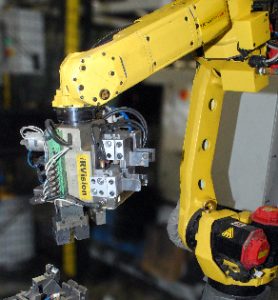

Blue Grass Metals invests in next generation technology. In addition to state of the art CNC and mechanical machinery, our manufacturing processes employ robotic cells for manufacturing and assembly of our customer parts and components.

Our systems provide increased efficiency, safety and productivity while providing consistent quality control built into each process. Our customers enjoy increased production, higher quality, greater flexibility and decreased costs with our high-end automation capabilities.

Blue Grass Metals employs lean manufacturing methods, just-in-time (JIT) production techniques, state-of-the-art equipment, and automation to achieve quality results. A lean fabrication system ensures that stock levels are efficiently managed in response to demand fluctuations and customer needs.

Our Technology Investments Provide:

- Just-in-Time Production Techniques for Manufactured Components and Assemblies

- Improved Efficiency and Increased Productivity

- Reduced Cycle Time and Consistent Cycles

- Less Waste / Scrap

- Complete Vision Inspection

- Full Assembly Verification

- Real-time Response to Demand Fluctuations

- Value-added Sub-Assemblies Done In-house

- Robotic Manufacturing Cells

- Sophisticated CNC Bending Equipment for Simple and Complex Designs

- Robotic Welding for First Quality High-volume Applications

- Precision Tooling and Design Services for Close-tolerance Applications